Trending...

- UK Financial Ltd Executes Compliance Tasks Ahead Of First-Ever ERC-3643 Exchange-Traded Token, SMCAT & Sets Date For Online Investor Governance Vote

- Golden Paper Launches a New Chapter in Its Americas Strategy- EXPOPRINT Latin America 2026 in Brazil

- Phinge Founder & CEO Robert DeMaio Ranked #1 Globally on Crunchbase, Continues to Convert Previous Debt Owed to Him by Phinge into Convertible Notes

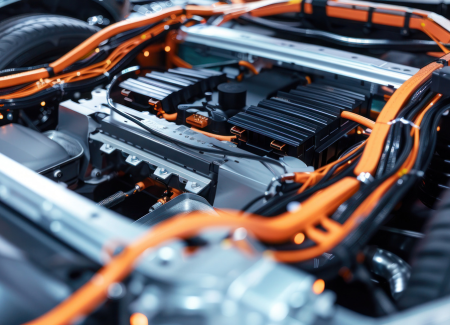

DALLAS, N.C. - PrAtlas -- Discover how one formulation enables cost-efficient, sustainable ESD packaging for the automotive industry without compromising performance.

Background

A leading German-based packaging manufacturer serving the automotive industry sought to enhance its offering of electrostatic discharge (ESD) safe polypropylene (PP) boxes used by major OEMs. The company had previously outsourced production but recently invested in its own production facility, signaling a strategic move toward expanding in-house manufacturing capacity to better serve its European customer base.

Challenge / Need

The customer was under significant cost pressure in a highly competitive market. The challenge was to meet strict ESD and mechanical performance targets while simultaneously reducing material costs and incorporating sustainable practices. The end customer—automotive OEMs—also demanded circularity and environmental compliance, adding complexity to material selection.

More on PrAtlas

Solution

Premix offered its conductive PRE-ELEC® compound, tailored for ESD packaging in the automotive sector. The standout feature was its ability to tolerate recycled content allowing integration of both generic and customer-specific regrind while maintaining key mechanical and conductive properties.

To verify this, dilution trials were conducted comparing the compound (0% additional regrind) with compound diluted by 10% of the customer's own regrind:

Surface Resistivity (Conductivity):

0% regrind: ~3.30E+04 Ω (excellent ESD performance)

10% regrind: 1.90E+05 Ω (still well within target conductivity range)

Impact Strength – Charpy Notched (ISO 179, +20 °C):

0% regrind: 58 kJ/m²

10% regrind: 54 kJ/m²

Impact Strength – Izod Notched (ISO 180, +20 °C):

0% regrind: 48 kJ/m²

10% regrind: 46 kJ/m²

These results demonstrated that PRE-ELEC® maintains its critical performance properties even with 10% regrind blended in—proving its robustness and suitability for circular economy applications.

More on PrAtlas

By enabling up to 40% (mentioned in our MSDS) regrind content in the compound and an additional 10% customer-specific regrind, Premix delivered a material solution that met both technical targets and cost efficiency goals for high-volume automotive packaging.

Results / Benefits

Cost Efficiency: The high regrind tolerance enabled significant material cost savings without compromising product quality.

Sustainability: By reusing internal waste and integrating recycled materials, the solution aligned with OEMs' sustainability goals.

Performance Assurance: Testing showed that the material retained key impact strengths despite the dilution with regrind.

The customer was highly satisfied, as Premix helped the packaging manufacturer remain competitive in a demanding market while advancing their transition toward a more circular production model.

Want to explore how Premix materials can support your packaging innovations? Contact us today at: https://www.premixgroup.com/premix-group/premix-in-the-us

Background

A leading German-based packaging manufacturer serving the automotive industry sought to enhance its offering of electrostatic discharge (ESD) safe polypropylene (PP) boxes used by major OEMs. The company had previously outsourced production but recently invested in its own production facility, signaling a strategic move toward expanding in-house manufacturing capacity to better serve its European customer base.

Challenge / Need

The customer was under significant cost pressure in a highly competitive market. The challenge was to meet strict ESD and mechanical performance targets while simultaneously reducing material costs and incorporating sustainable practices. The end customer—automotive OEMs—also demanded circularity and environmental compliance, adding complexity to material selection.

More on PrAtlas

- Are You Hiring The Right Heater Repair Company in Philly?

- Appliance EMT Expands Professional Appliance Repair Services to Hartford, Connecticut

- Java Holdings LLC Acquires +Peptide, Expanding Portfolio Across Coffee, Science, and Functional Nutrition

- OneSolution® Expands to Orlando with New Altamonte Springs Implant Center

- Indian Peaks Veterinary Hospital Launches Updated Dental Services Page for Boulder Pet Owners

Solution

Premix offered its conductive PRE-ELEC® compound, tailored for ESD packaging in the automotive sector. The standout feature was its ability to tolerate recycled content allowing integration of both generic and customer-specific regrind while maintaining key mechanical and conductive properties.

To verify this, dilution trials were conducted comparing the compound (0% additional regrind) with compound diluted by 10% of the customer's own regrind:

Surface Resistivity (Conductivity):

0% regrind: ~3.30E+04 Ω (excellent ESD performance)

10% regrind: 1.90E+05 Ω (still well within target conductivity range)

Impact Strength – Charpy Notched (ISO 179, +20 °C):

0% regrind: 58 kJ/m²

10% regrind: 54 kJ/m²

Impact Strength – Izod Notched (ISO 180, +20 °C):

0% regrind: 48 kJ/m²

10% regrind: 46 kJ/m²

These results demonstrated that PRE-ELEC® maintains its critical performance properties even with 10% regrind blended in—proving its robustness and suitability for circular economy applications.

More on PrAtlas

- Dugan Air Donates $10,000 to Indian Creek Schools

- Robert DeMaio, Phinge Founder & CEO, Ranked #1 Globally on Crunchbase, Continues to Convert Previous Debt Owed to Him by Phinge into Convertible Notes

- 2025: A Turning Point for Human Rights. CCHR Demands End to Coercive Psychiatry

- The 22% Tax Reality: Finland's New Gambling Law Creates a "Fiscal Trap" for Grey Market Casino Players

- Phinge Founder & CEO Robert DeMaio Ranked #1 Globally on Crunchbase, Continues to Convert Previous Debt Owed to Him by Phinge into Convertible Notes

By enabling up to 40% (mentioned in our MSDS) regrind content in the compound and an additional 10% customer-specific regrind, Premix delivered a material solution that met both technical targets and cost efficiency goals for high-volume automotive packaging.

Results / Benefits

Cost Efficiency: The high regrind tolerance enabled significant material cost savings without compromising product quality.

Sustainability: By reusing internal waste and integrating recycled materials, the solution aligned with OEMs' sustainability goals.

Performance Assurance: Testing showed that the material retained key impact strengths despite the dilution with regrind.

The customer was highly satisfied, as Premix helped the packaging manufacturer remain competitive in a demanding market while advancing their transition toward a more circular production model.

Want to explore how Premix materials can support your packaging innovations? Contact us today at: https://www.premixgroup.com/premix-group/premix-in-the-us

Source: Premix

Filed Under: Automotive

0 Comments

Latest on PrAtlas

- Leimert Park Announces Weeklong Kwanzaa Festival & Kwanzaa Parade Celebrating Black History, Culture, and Community

- Renowned Alternative Medicine Specialist Dr. Sebi and His African Bio Mineral Balance Therapy Are the Focus of New Book

- Psychiatric Drug Damage Ignored for Decades; CCHR Demands Federal Action

- Why Millions Are Losing Sexual Sensation, And Why It's Not Age, Hormones, or Desire

- Justin Jeansonne An Emerging Country Singer-Songwriter Music Fans Have Been Waiting For…a True Maverick

- Russellville Huntington Learning Center Expands Access to Literacy Support; Approved Provider Under Arkansas Department of Education

- UK Financial Ltd Launches U.S. Operations Following Delaware Approval

- Pinealage: the app that turns strangers into meditation companions — in crowdfunding phase

- "Micro-Studio": Why San Diegans are Swapping Crowded Gyms for Private, One-on-One Training at Sweat Society

- Beycome Closes $2.5M Seed Round Led by InsurTech Fund

- Tru by Hilton Columbia South Opens to Guests

- Christy Sports donates $56K in new gear to SOS Outreach to help kids hit the slopes

- "BigPirate" Sets Sail: A New Narrative-Driven Social Casino Adventure

- Phinge CEO Ranked #1 Globally by Crunchbase for the Last Week, Will Be in Las Vegas Jan. 4-9, the Week of CES to Discuss Netverse & IPO Coming in 2026

- Women's Everyday Safety Is Changing - The Blue Luna Shows How

- Microgaming Unveils Red Papaya: A New Studio Delivering Cutting-Edge, Feature-Rich Slots

- 5-Star Duncan Injury Group Expands Personal Injury Representation to Arizona

- The End of "Influencer" Gambling: Bonusetu Analyzes Finland's Strict New Casino Marketing Laws

- AI-Driven Cybersecurity Leader Gains Industry Recognition, Secures $6M Institutional Investment, Builds Momentum Toward $16M Annual Run-Rate Revenue

- TRIO Heating, Air & Plumbing Now Ranks #1 in San Jose